Should I outsource my electronic production?

Considering Contract Manufacturing

For decades, a highly competitive, international market has driven companies to seek out alternatives in terms of successful and efficient organisational forms. A trend favoured by globalisation and increasing specialisation is outsourcing. That said, the outsourcing of business areas is often viewed sceptically. And rightfully so?

Poor reputation of outsourcing

Due to the number of headlines in the past years regarding the outsourcing of large companies, the term “outsourcing” is associated with the loss of jobs. Instinctively, mainly negative changes are anticipated for the company’s outsourced areas of activity. But it is not always merely the desire to benefit from cheap production abroad which drives such a corporate restructuring. To the contrary, it is more the array of opportunities that may arise from outsourcing. This may range from synergy effects via efficient collaboration to a lack of space at the company’s premises. Outsourcing is not always associated with lost jobs. Sometimes this important step helps to secure precisely these jobs. Companies can gain access to a broad variety of services and production facilities at home and abroad by means of outsourcing.

Increasing demand for services from external providers

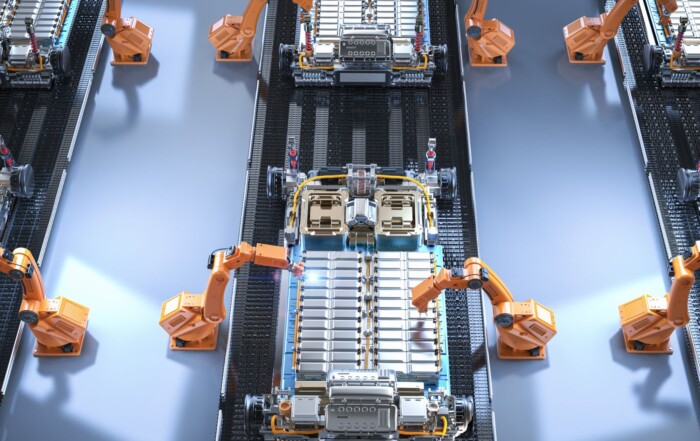

For years, outsourced electronic production has been very popular. High-tech products require sophisticated manufacturing processes and qualified personnel, and are subject to many regulations. To remain competitive on the international market, companies must constantly continue to develop. For some companies, this means giving up a range of tasks that are dispensable to them. For example, companies hand over production to external service providers if the resulting costs prove cheaper than in-house production or the company’s options in terms of further development have already been exhausted. Those who want more than a mere assembly service seek out a reliable EMS service provider. They offer not only production, but also an extensive service, from development to after-sales. This service is also exhibiting strong growth at national level. Consequently, businesses are not necessarily reliant on external production in third countries, but can also make use of the services of regional providers. A negative attitude towards outsourcing is therefore not always justified. Its convincing benefits effectively supplant any concerns.

But what arguments encourage companies to relinquish such concerns as the disclosure of company information, high logistics and communication costs, and dependency?

You can benefit from the following advantages by outsourcing electronic production:

Should I outsource my electronic production to an external EMS service provider?

According to all these optimistic arguments, the answer to this question would clearly seem to be “yes”. Unfortunately, things are not quite that simple. For each company, an individual assessment of the specific advantages and disadvantages needs to be carried out in order to come to a reasonable decision. Depending on the industry in question or the potential within your company, some advantages of external production may already not be pertinent. The risks to your company should also be thoroughly considered. Comparing all positive and negative aspects should prove helpful in taking a decision.

In general, outsourcing the production of electronic components is an excellent opportunity for many companies to advance their development particularly in Germany, due to high-quality standards, strong specialist competence, and regional proximity. Companies looking into outsourcing should first conduct extensive research and selection processes in which they thoroughly evaluate their future business partners’ communication channels, traceability, transparency, and quality, before subsequently minimising risks such as dependence.

picture: ©ra2studio by adobe stock

Share This Content

Contract Manufacturing at InnoSenT

high-quality – client-oriented – individual

Competent EMS providers such as InnoSenT GmbH offer a wide range of reliable services in the field of electronic production which may prove useful to your company. Through our certifications and qualifications, clients can rely on the quality of services provided. More information on electronic production at InnoSenT can be found on our website.