Play it safe –

Radar for safety applications.

A large number of our technological achievements have been developed for our safety. We strive to feel safe. We thus protect ourselves against dangers in our everyday life, for example when driving or at work, and we make utilise a variety of electronic and mechanical devices for this purpose.

Sensors play a crucial role in this, as a key technology. They contribute to improving safety in a wide range of uses.

For several years now, they have also increasingly found their way into modern factory facilities. Because the requirements in terms of designing safe workplaces are growing, and so are the personal-protection-related tasks involved. In addition to production automation, sensors fulfil a safety function, by protecting people from injuries caused by machines, vehicles, or objects, or from damage caused by collisions. When it comes to personal protection, the technology’s reliability and measurement accuracy is vital. Usually, certain zones around machines are secured in order to enable safety measures to be carried out when people approach the machines or are present nearby.

Measurement technology for safety applications

When it comes to securing areas within a smart factory, two measurement technologies can be found: established, tried-and-tested laser technology and radar technology which is still emerging in this field. Which sensor technology is the better choice depends heavily on the application in question. The two technologies differ in terms of their operating principle and their associated strengths and weaknesses, rendering each one more or less appropriate for a given application area.

Laser sensors scan their environment and continuously emit electromagnetic waves. The laser beam creates a sort of barrier. As soon as a person reaches the specified scanning area, they interrupt the laser beam.

When they cross this threshold, the device detects that a person is approaching the machine and their distance from the sensor.

To cover two dimensions, the laser scanner rotates, creating light grids. In combination with reflectors, the sensors secure hazardous areas by forming light barriers, curtains, or protective fields.

Laser boasts very high resolution. The sensors are very sensitive and precise, because they also detect very short interruptions by small objects. For example, they detect a hand in front of a mechanical and automated device, as well as entire working areas through the use of fences.

Radars also emit electromagnetic waves. The sensors emit microwaves as pulses, which spread out freely in space at the speed of light and reflect back from surfaces within the coverage range. This enables the device to record the speed and distance. This information can be used to precisely position the objects. Radars are ideally suited for detecting motion. They can even perceive slight vibrations or breathing movements within the coverage range.

Radar boasts advantages over laser technology, especially in harsh environments and outdoor areas. The technology is completely unaffected by dirt, dust, vapour, darkness, or light reflections. Even extreme temperatures do not impair its functionality.

Learning new sensor solutions learn from other sectors

Radar sensors have already proven their capabilities in many other applications. However, they are still quite new to collision protection and personal protection. The frequency bands that provide the resolution necessary for these applications have not been available for long. Only thanks to the intense development work by radar experts in recent years has a significantly better resolution and outstanding performance been able to be achieved.

So far, laser technology has thus dominated in the safety sector, and radar technology is still struggling with outdated negative presumptions. Many assume that radar sensors can detect only moving objects. But the technology is undergoing tremendous, rapid development.

Because other industries have recognised the technology’s potential and are pushing for progress. For instance, radar sensors have long been contributing to road safety in the form of driver assistance systems. Research and development have progressed so far in this area that high-resolution and highly integrated systems with impressive performance are in use. And industrial and safety applications are now benefiting from this as well. Thanks to three-dimensional detection of its surroundings, radar boasts great potential not only for outdoor use or in challenging environments, but also in smart factories.

All-round protection is becoming increasingly important

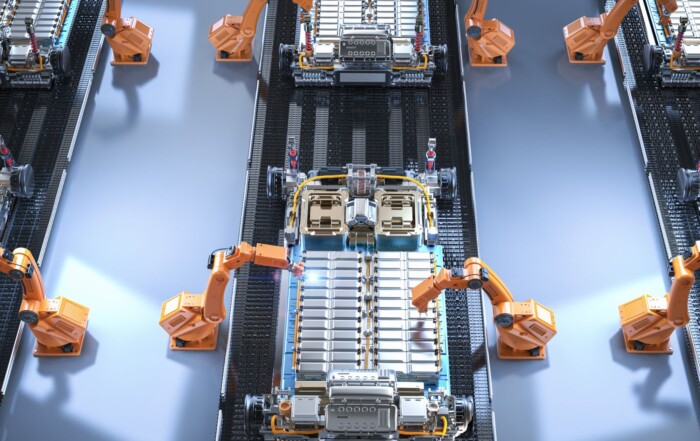

Modern factory halls are becoming more and more autonomous. Work tasks carried out between man and machine often go hand in hand. Various transport units automatically manoeuvre heavy loads from one place to another. Autonomous vehicles are increasingly being used. They move freely in space directly next to a large number of working people as well as other machine units or robot arms performing automated activities. Without sensors for personal and collision protection, this would be unthinkable.

After all, injuries must absolutely be avoided. To achieve reliable protection in smart factories, the sensors must be equipped with high-precision environmental sensor technology.

Two-dimensional monitoring quickly reaches its limits, and lasers miss objects protruding from above through their exclusively planar view. If such objects are not exactly in the line of sight of the laser scanner or the machine is in a titled position, this results in false detections. Radar enables the complete environment to be detected in 3D through additional height detection.

Expectations and tasks are on the rise.

Another trend is the increasingly difficult distinction between pure protection and automation technology. These advanced technologies usually offer more than just distance measurement for collision protection. Radar provides comprehensive object information: the systems detect speed, distance, direction of movement, RCS, and angular position in azimuth and elevation. This allows further functions to be fulfilled beyond personal protection. And that includes more than simple statistical tasks. The sensors can simultaneously be used for navigation, positioning, and safety purposes. In order to keep production downtime as low as possible, these modern sensors should also have different safety ratings. For example, a passing person may not always mean everything needs to completely stop, but a warning is helpful.

The factory of the future – not without advanced sensor technology.

In order to take on such complex tasks, a great deal of development work within the industry is currently going into sensor technology and signal processing. In order to ensure that all events are recorded precisely and correctly, the developers are working on advanced algorithms that filter interfering factors and optimise performance. Previous solutions have usually focused on a function, such as collision protection. But the sector expects more, because the technology is capable of more. The ball got rolling with the first advanced radar systems for robotics. InnoSenT is also advancing this development through research projects and is working on new solutions for personal protection.

Header Picture Source: © by adobestock.com

Share this Content

Radar sensors for the smart factory

Robotics, automation, safety & collision protection

With industrial robots, more and more sensors are finding their way into modern factories. By detecting the environment and events, they enable safe interaction between man and machine and protect against collisions. Without the integration of sensors, machines or robots cannot react to their environment. Typical applications are automation, personal protection, navigation, positioning, autonomous vehicles and collision protection. Radar offers three-dimensional environment detection and reliable, precise detection in harsh industrial environments.